Mobile plant and pedestrians don’t (or shouldn’t) mix. A NZ company was sentenced in March for a fatality because ‘there should have been an enforced exclusion zone on site to separate workers from machinery with the ability to kill or injure.’ (WorkSafe’s Chief Inspector, Steve Kelly) Here’s where to start when you get serious about segregating people and vehicles.

Start with a comprehensive site traffic management plan

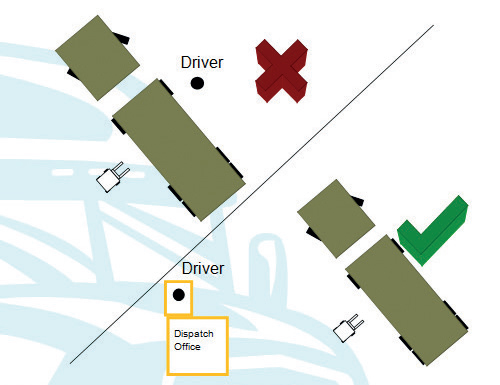

Workplace layout is key in arranging a safe and productive workplace.

Sometimes knowing where to start is a major roadblock.mHaving a pedestrian safety expert share their ideas and advice could be all you need.mWe offer a free onsite 60 minute consultation service to kick start your journey to develop and implement a traffic management plan.

2 Areas of concern

1. Pedestrian Safety

Aim: To conduct workers, management and visitors from Point A to Point B while avoiding random, unplanned encounters with forklifts, trucks, loaders, and any other machinery.

How to keep them apart:

- Signs – Pedestrians need to be shown clearly where they can and cannot be.

- Barriers. Painted lines on the floor are good. Physical barriers are better.

- Visibility – Pedestrian walkways should be highly visible and obvious to any machinery operators in the vicinity.

No blind corners, no surprises. You can see through or over all our pedestrian barriers – even the tough Forksafe ones that can resist an attack by a forklift! [Watch PedSafe Video here]

- Gates. Designated crossing points should be guarded by a gate. The act of opening a gate gives pause before crossing. It’s easy to add a self-locking gate as part of our Pedsafe pedestrian barrier system.

- Signs and warning devices (flashing lights) should mark out potential hazards.

2. Pedestrians working around powered mobile plant (trucks, vans, load-shifting machinery)

Delivery and pickup of goods, loading and unloading of equipment and merchandise all present hazardous situations.

Worksafe NZ suggests:

- One-way systems

- Mirrors on blind spots

- Separate entrances for people and plant

- Speed management using bumps or signage

- Specially marked reversing or turn-around areas.

- Designated loading/unloading areas

- Clearly identify and delineate mobile plant exclusion zones

- Identify designated areas to board or alight from plant to prevent people from entering exclusion zones

- Provide a designated safe area for drivers (while loading and unloading)

Human error – responsible for up to 90% of workplace accidents

So, how do we make an ‘enforced exclusion zone’?

To use an aviation term, if a worker is suffering from ‘lack of situational awareness’, i.e. ‘he’s spaced out’, due to physical or mental stress or maybe just dreaming about the beach, he might ignore all signs and warnings. Or even his safety training.

At this point only a barrier would keep him safe. However, it doesn’t always work to install permanent barriers – sometimes you need the space to be open. That’s when we suggest expandable barriers. They concertina out to the length you want, and fold neatly out of the way when their job is done.

In our free onsite consultation our representative will work with you to identify specific danger areas. Let us know!

Useful resources:

RISK FACTOR CHART

https://www.dexsafe.com/nz/download/274/

OUR BARRIER RANGE

https://www.dexsafe.com/nz/download/272/